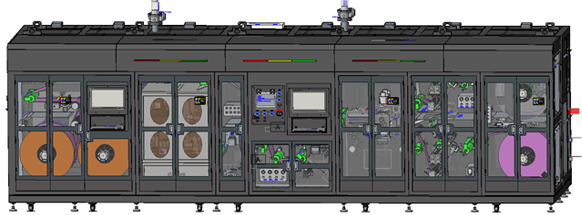

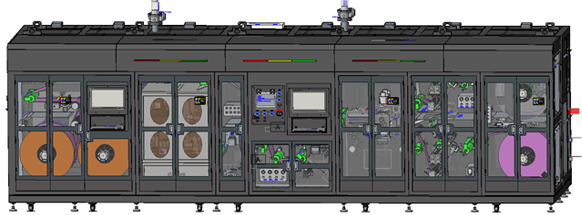

Main Advantages:

Dual-axis automatic unwinding, deviation correction and

Tension control

Visual inspection for upper and lower surface defects of the

electrode sheet

Maximum flexibility in terms of tab shape and cell chemistry

Automatically adjust the tab gap to achieve variable tab

cutting

The cutting process has several dust removal designs, e.g.

winding dust removal, there is no dust accumulation in the

cutting area Has cutting MARK hole function and R angle

function

Has CCD online detection of tab quality and size, no scrap

cutting

Equipped with a guide plate, tab pressing rib and other

mechanisms to prevent tab folding

Double-side dust removal and waste compression mechanism to

make sure there is no secondary pollution when cleaning

scissels

Equipment Application:

Be applied for laser cutting and stacking in material boxes

for tabs when fast and precise processing is required.

Be applied for laser forming for tabs and electrode sheet

fillet.